There are many different types of porcelain and many techniques. Common among these are that they are all burned at high temperatures and that many are decorated with underglaze decoration. Although some factories have just made colored print directly on the plate (called silk print and the like).

Good examples of quality porcelain with underglaze decoration are the Danish Christmas plates from Royal Copenhagen and Bing & Grondahl that involve a high degree of artistic work. Read more about the fascinating process that is used for the production of porcelain plates.

The plate process

The motif

The whole process starts with the artist drawing the motif. The motif is made to fit the dimensions of the Christmas plate and is then given to the modeller.

The modeller engraves the motif into the plaster form that becomes the base model for alle the Christmas plates. The engraving of the plaster form is a difficult process, requirering great skill from both the artist and the modeller. The artist must draw the motif correctly according to the measurements and curvature of the Christmas plate and the modeller must transfer the finished motif to the plaster form by hand engraving. This is for the steady hand.

The finished plaster form curves inwards in the same way as the Christmas plates that it is the model for, so to transfer the motif to the Christmas plates the plaster form is used to make work forms that are then used to press the motif into the Christmas plates. The work forms can only be used a limited number of times before they have to be discarded and new work forms used. When the production of the Christmas plate of the year has ended the plaster form is destroyed to prevent the reproduction of the same year.

The plate

The actual Christmas plates are like all porcelain produced from a mixture of kaolinite, feldspar and quartz mixed in water. Most of the water is squized from the mixture to make it into a mass with lower water content that can be shaped. This mass is then used to make plates and gets the motif by being pressed in the work forms.

After shaping and pressing in the motif the new Christmas plates are burned for the first time at a temperature of 900 degrees celsius. This temperature hardens the plate to make it able to resist the further treatment, but still leaves it porous enough to absorb the paint.

The color

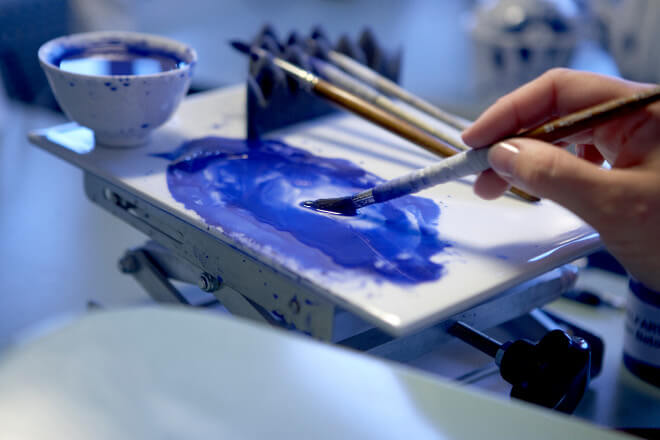

The front of the Christmas plates are now spray painted in the well-known cobalt blue color, so the entire front of the plate with the motif is covered and ready for the next step.

Now the porcelain painters can get to work with their tools to bring forth the motif of the plates.

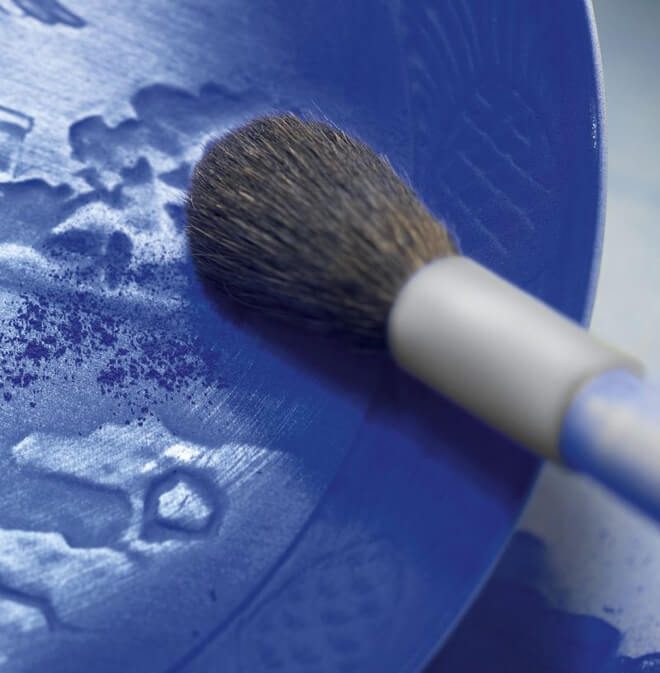

First step is to wipe off a good part of the spray paint to make the relief stand out more clearly with the colors differing between elevations and depressions.

Now the porcelain painter must add a bit of paint to perfect the nuances of the Christmas plate. This is where the trully lifelike appearance is achieved on the Christmas plates.

Signing and glazing

Lastly the porcelain painter signs the individual plates that are now ready for glazing. The Christmas plates are dipped in the porcelain glaze to completely cover the plate. Then the plates are prepared for the final trip to the porcelain ovens.

The glazed plates are put in forms of carborundum to protect them against direct contact with the fire. The Christmas plates are now burned at a temperature of 1400 degrees celsius making the porcelain tight and strong. The Glaze melts and becomes a clear layer of glass above the paint. The blue colour is now protected beneath the glaze that is very durable.

Sorting

The Christmas plates are now ready to be checked for faults. During the sorting all plates with faults are removed. Quite a large number of plates are removed during the sorting process, where about half are destroyed due to faults. The faults can be iron stains, error in the paint, cracks in the glazing and bubbles in the porcelain. In the past as the error rate was even higher some of the best faulty plates were sold as 2nd quality.

When the quality check is done the plates that are distributed for sale are left.

Here we have followed the making of the Christmas plate 2011. The Danish Christmas plates are known for their high quality and relief engraving that is only possible through the arduous process above.

Here you will find the entire series of Christmas plates from Royal Copenhagen.

You can also see the fine decorations of the whole series of Bing & Grondahl Christmas plates that are made in the same way.

There are many other plates made in a similar way, see all the plates here!

Don't miss free tips and a lot of great sales

DPH Trading

Løkkegravene 49

5270 Odense N, Denmark

CVR-no.: DK61086013

Follow us on social media:

We are e-approved

We are e-approved